Ribbed Smoked Sheet Rubber Manufacturing Process

Ribbed smoked sheet manufacturers suffer quality problem due to impurities settling in the rubber during the manufacturing process.

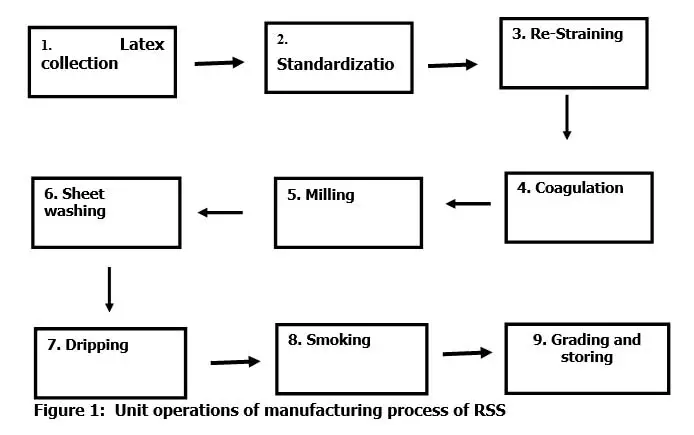

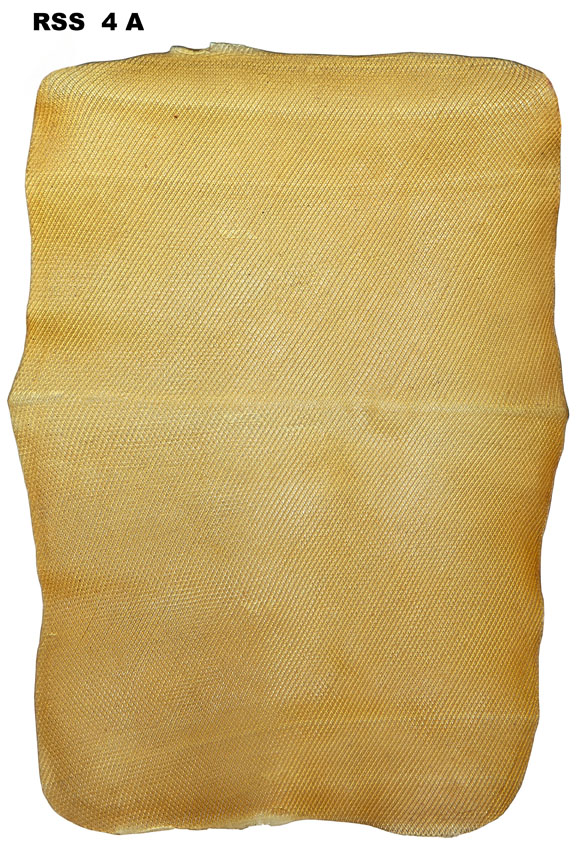

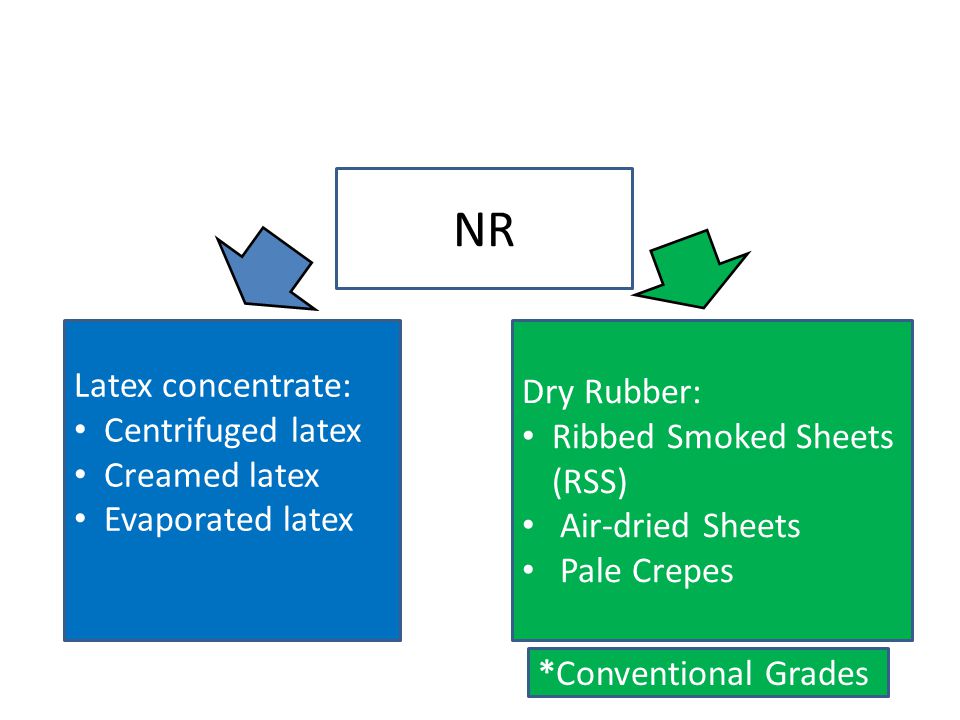

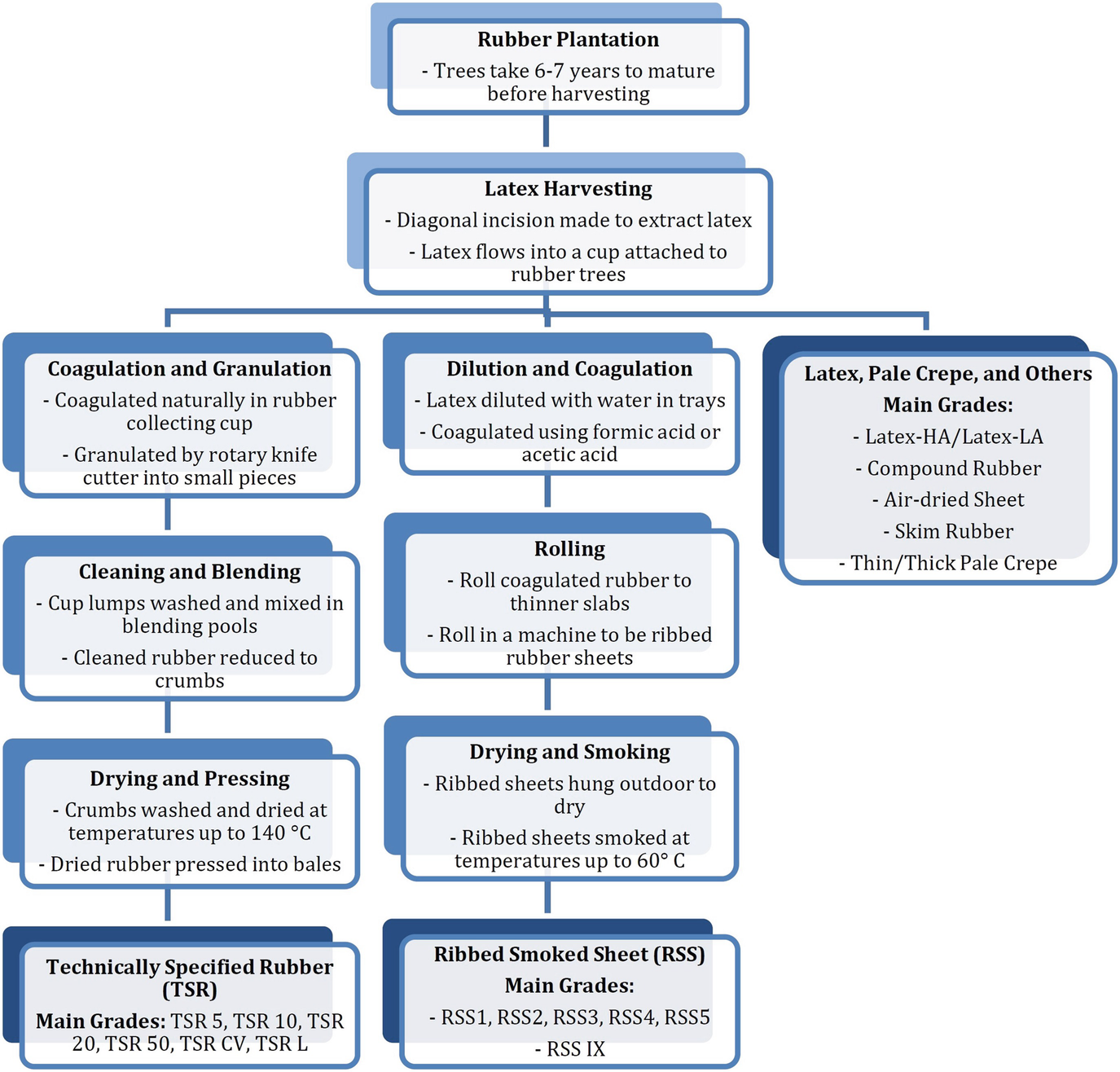

Ribbed smoked sheet rubber manufacturing process. Ribbed smoked sheets are processed from fresh field latex collection from well managed rubber plantations by using modern processing techniques the various ribbed smoked rubber sheets rss produced are rssi rssii rss iv and rss v the higher grades of rss i and rss ii are mainly used in the medical and engineering industry the lower grades such as rss iii rss iv and rss v are used for manufacturing of automobiles tyres retreading materials and other general rubber products. Originally most of the solid rubber used was in the form of ribbed smoked sheets or rss rubber. Natural rubber ribbed smoked sheet rss production process involves a drying step in a wood smoke dryer. If you need natural rubber smoke sheet rss3 please kindly contact us hotline 84 775 914 078 whatsapp and wechat email sales23.

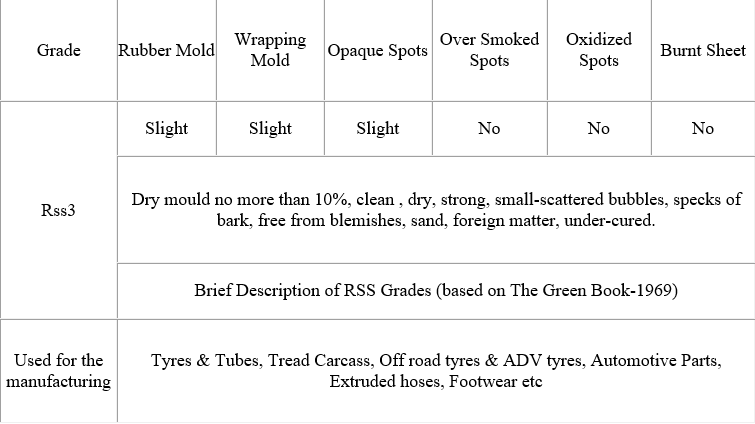

Natural rubber latex is traditionally converted into sheet form through careful coagulation and subsequent milling process on two roll mills. Grading of rss is done based on the grade descriptions and specifications defined in the the green book of international rubber quality and packing conferences as rss 1x rss1 rss2 rss3 rss4 and rss5 over 70 of the production of natural rubber is processed as ribbed smoked sheet. Among them ribbed smoked sheet rss has been the major form of raw rubber produced in sri lanka above 40. 2002 john wiley sons inc.

Ribbed smoked sheets produced in thailand are of mid to low quality. Ribbed smoked sheets rss ribbed smoked sheet rss is marketed based on visual assessment of quality. The purpose of this work was to know whether this smoke drying step affected the lipid. Tree lace and unsmoked sheets can also be used in producing block rubber.

There are many types of sheets rubbers namely ribbed smoked sheet rubber air dried sheet tuber and sun dried sheet rubber depending on the drying methodology used. By the early 1970s however tsr or rubber was introduced into the market. The room was. The ribbed sheets were hung in the room for seventy two hours.

The ribbed smoked sheet was washed with water absolutely. In this process the wood was burnt in a windows as well as doors opened room at about 38 50 c temperature. Please see the table below for a complete list of the all the major tsr grades commonly produced. We are vietnam natural rubber smoke sheet manufacturer.