Review Rubber Torch Down Roof With Insulation

This 25 year old 2 ply modified bitumen torch down rubber roof coated with aluminum asphalt paint which is meant to protect the surface against harmful uv rays it has had many years of scattered debris foot traffic from a rooftop a c and ventilation units being serviced yet there is no indication that repairs have ever been needed.

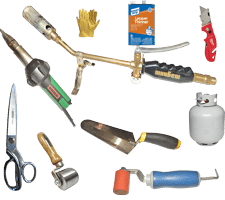

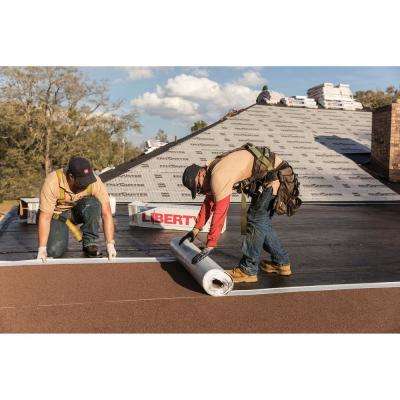

Review rubber torch down roof with insulation. Torch down roofs can also provide protection from heat. Two layer and three layer torch down roof systems. Torch down roofing is made of a rubberized asphalt material that is melted to the roof of a home using a torch. Finishing the roofing once a nice smooth surface of sheathing was in place on the flat roof insulation a layer of 28 fiberglass base sheet was nailed in place with large head roofing nails.

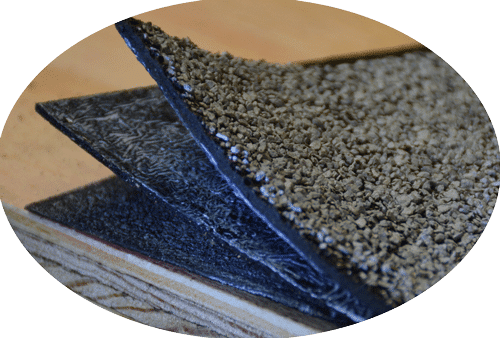

Typical installations use a three layer system. Rubber roofing commonly comes in a roll or sheet often referred to as a membrane. Perforated underlay a 2mm underlay layer then 4 5mm felt. Discover the various components of a torch down roof and the materials used to manufacture it.

A two layer torch down roof consists of one base sheet and one smooth cap sheet. This image is a torch down rubber roof that was installed over 30 years ago. Unlike the single ply roofing systems as in tpo and epdm the 2 ply mb system will need little to no maintenance during its life. Despite it not being the stronger of the two felt roofing is still a reliable choice.

It s reliable and robust. Two layer torch down roofing may cost less. On average you ll spend about 7 500 for 1 500 square feet with a range of 6 000 to 18 000 due to the complexity of the installation type and thickness of insulation roof pitch location accessibility and old roof removal costs can exceed 24 000. The roof is still in good condition and has no need for replacement or repair.

Torch down roofs are composed of two or more layers of a modified asphalt membrane applied with an open flame torch. Modern torch on felt roof. This is a modified bitumen torch down rubber membrane that was installed over 20 yeas ago. Plus learn the advantages and disadvantages of a torch down roof system.

A three layer torch down roof features the same base and cap sheets as well as an additional cap sheet with a granulated surface. There are two different types of torch down roofing systems. Torch on felt roofing simply describes the method in which the material is applied. Firstly torch down roof coatings are resistant to leaks.

A single ply granulated modified bitumen roofing material was then torched down as the final layer of roofing material. Any homeowner who is in need of strong yet flexible water resistant roofing material should go with this type of product.